Introduction

While this book is not

intended as a comprehensive course in electricity and magnetism

there are a few

principles that are so ubiquitous in functional magnetic resonance that

they appear repeatedly

throughout this text and therefore warrant this brief overview.

Charge

Electrical charge is

considered to be a fundamental property of materials. Physicists

recognize that charge

exists in only two forms, positive and negative, and that it is

quantal in nature,

with the smallest amount of charge being that of a single electron or

proton, each being

exactly 1 unit of negative or positive charge, respectively. A single

unit of charge is

extremely small, of course, and charge is more commonly measured in

units of Coulombs, equivalent to about

6.242 X 1018 unit

charges. Positive and negative

charges exhibit a

strong attractive force, whose magnitude is proportional inversely to

the square root of the

distance that separates them. In its most stable state, bulk matter

has a net charge of zero, meaning that it contains an

identical number of positive and

negative charges.

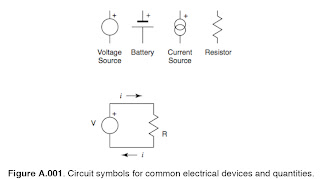

Voltage

When charges become

separated by distance, the presence of an attractive force between

implies an increase in

potential energy, which is released when the charges are moved

together. This energy

difference is known as Voltage and is measured, naturally, in

Volts. Because the

potential energy of the Voltage is also measure of the force that would

tend to move the

charge, it is known also as the potential difference, or simply the

potential, the “electromotive

force” or the e.m.f. and

these terms are used

interchangeably, which

can at times be confusing. Batteries are familiar voltage sources

that rely on chemical

means to store potential energy. For convenience, the units of

Volts are defined in

terms of other fundamental physical constants and units. One

Joule of work is required to move one Coulomb

of charge through a potential difference

of 1 Volt. In

practice, this means that a Coulomb is actually defined to set unit values of

Volts and Joules.

Voltage must always refer to the energy difference

between two points.

It is never actually

correct to discuss the Voltage at a point, though you will often see

such a statement. In

those cases, the reference point is assumed implicitly, usually to

refer to a “ground” or

common point in an electrical circuit.

At the atomic level

charges may become separated. In some molecules, such as salts like

sodium chloride, the electronegativity of one

atom (chloride) is so much greater than

that of the other

(sodium) that in a covalent atomic bond between these elements the

electron or electrons

are almost completely transferred from one atom to the other.

Such bonds are

dissociated easily in aqueous solution so that the individual atoms now

become “ions” or charged particles. In water, the atoms of

salts appear in ionic form, so

that atoms of sodium,

potassium, chloride, magnesium and many others move relatively

freely of their

oppositely charged complement. Not only atoms, but also molecules, can

exist in ionic form,

and many proteins, for example, carry a net negative charge. Of

course some ions may

be quite large and there may be physical impediments to their

motion that result in

different bulk properties for ions and small charges, such as

electrons. These

effects are significant in some circumstances, but in most of the

discussion that follows, and throughout most of this book, we can consider the

properties of ions interchangeably with the properties of charge.

Current and Resistance

The motion of charge is known as current; specifically, the current, i, is equal to the

change in charge, Q, with time, so that:

Where V is the Voltage, i is the current, and R the resistance. Materials whose resistance

is extremely high are termed insulators and those whose resistance is low are called,

conductors. Good insulators may have resistance of gigaOhms (109 Ohms) or more,

whereas good conductors, such as copper wire, will have resistance of microOhms. More

accurately, we refer to resistivity, which is the measured resistance normalized by the

area and length of a conductor, so that it is a material property. Most biological

materials fall in a more intermediate range with resistances of thousands to millions of

Ohms. In a perfect conductor, where the resistance is zero, the voltage at all points along

the conductor is identical. In general, moving charge from a source of higher potential

energy to lower (current flowing from positive to negative ends of a source) must result

in energy dissipation. Resistors dissipate this energy as heat.