Directional drilling is the art and science involving the intentional deflection of a wellbore in a specific direction in order to reach a predetermined objective below the surface of the earth

- At one time it was thought that all wells were vertical

- Methods to measure deviation were developed in the 1920’s (initially acid bottle)

- Directional drilling developed after 1929 when new survey instruments were available (inclination and direction)

- The first controlled directionally drilled well was drilled in the Huntington Beach Field in 1930 to tap offshore reserves from land locations

- Directional drilling became more widely accepted after a relief well was drilled near Conroe, Texas in 1934

- Today, directional drilling is an integral part of the petroleum industry

- It enables oil companies to produce reserves that would not be possible without directional drilling

- One of the primary uses of directional drilling was to sidetrack a well even if it was to go around a stuck BHA

- Sometimes multiple sidetracks are used to better understand geology or to place the wellbore in a more favorable portion of the reservoir

- Straight hole drilling is a special application of directional drilling

- To keep from crossing lease lines

- To stay within the specifications of a drilling contract

- To stay within the well spacing requirements of a developed field

- Drilling multiple wells from a single structure or pad

- Most offshore development would not be possible without directional drilling

- Inaccessible surface location

- Drilling in towns, from land to offshore and under production facilities

- Drilling around salt domes

- Salt can cause significant drilling problems and directional drilling can be used to drill under the overhanging cap

- Steeply dipping sands can be drilled with a single wellbore

- Fault drilling

- In hard rock, deviation can be a problem

- Sometimes the bit can track a fault

- Drilling at a higher incident angle minimizes the potential for deflection of the bit

- Relief well drilling

- Directional drilling into the blowout when the surface location is no longer accessible

- Very small target and takes specialized equipment

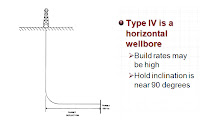

- Horizontal drilling

- Increasing exposure of the reservoir to increase productivity

- Multilateral drilling

- Drilling more than one wellbore from a single parent wellbore

- Extended reach drilling wells are characterized by high inclinations and large departures in the horizontal plane

- Extended reach wells are wellbores where the horizontal departure is significantly higher than the true vertical depth of the well, which is the horizontal departure – TVD ratio (HD/TVD)

- Extended reach wells have been drilled with HD/TVD ratios greater the 6/1.BP drilled a well at Wytch Farm with a measured depth of 34,967’ (10,658 m), a TVD of 5,266’ (1,605 m) and horizontal departure of 33,181’ (10,114 m)