MILLING OPERATIONS

Overview

Junk mills are the surest way to eliminate junk in the hole. There are various

mills that can be used in different circumstances. For example, the insert

type of mill is best suited for milling pipe or tools anchored securely in the

well bore; however, chatter, vibration or loose junk are detrimental to the

inserts.

mills that can be used in different circumstances. For example, the insert

type of mill is best suited for milling pipe or tools anchored securely in the

well bore; however, chatter, vibration or loose junk are detrimental to the

inserts.

صورة 15

Types of Mills

1- Insert Type

Can be used for:

• pipe/tools anchored securely in the wellbore.

Caution: Chatter, vibration, or loose junk are detrimental to the

inserts.

• pipe/tools anchored securely in the wellbore.

Caution: Chatter, vibration, or loose junk are detrimental to the

inserts.

2- Crushed Tungsten Carbide Mills

Can be used for:

• almost anything, except in hard abrasive formations.

• almost anything, except in hard abrasive formations.

3- Skirted Flat Bottom Or Concave Type Mill

Can be used for:

• flared or burred top of fish prior to engagement with an

overshot. Because the skirted mill is stabilized and the

fish is contained within the skirt, it cannot slip off

• flared or burred top of fish prior to engagement with an

overshot. Because the skirted mill is stabilized and the

fish is contained within the skirt, it cannot slip off

4- Blade Type Mill

Can be used for:

• junk or cast iron material which will break up.

Features:

• Rugged, durable construction

• Concave, convex, and flat-bottom designs available

• Dressed with tungsten carbide inserts for stationary fish

or junk

• Dressed with crushed tungsten carbide for loose fish or

junk

• Improved cooling during milling

• Increased milling efficiency

• junk or cast iron material which will break up.

Features:

• Rugged, durable construction

• Concave, convex, and flat-bottom designs available

• Dressed with tungsten carbide inserts for stationary fish

or junk

• Dressed with crushed tungsten carbide for loose fish or

junk

• Improved cooling during milling

• Increased milling efficiency

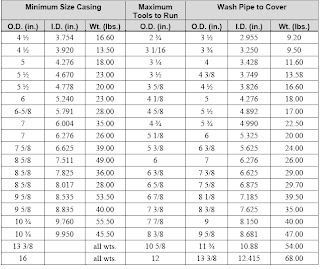

5- Pilot Mill/Diamond Point

The Pilot Mill/Diamond Point is used for milling tubing, casing,

liner hangers, liners, drill pipe, drill collars, wash pipe, or

perforated liners.

Using Pilot Mills:

• Select a pilot mill with a blade O.D. ¼ inch larger than

the O.D. of the tool joint or coupling of the fish milled.

The pilot O.D. should be the same as the drift I.D. of the

fish.

• Determine the best rotary speed and weight to run a pilot

mill for each job. Conditions may change from one pilot

milling job to the next in the same well. The change may

require different rotary speeds and weights at different times. In the absence of experience, start with a speed of

between 80 and 100 RPM’s and a tool weight of 2,000

to 6,000 lbs. Vary the speed and weight to obtain the

best results.

• If milling a liner or casing that is gun-perforated,

damaged with a spear, or collapsed, use 60 RPM’s and

2,000 lbs. of weight or less.

• A sudden drop in the milling rate while milling swaged

casing may be caused by a loose ring of steel formed at

a joint or weld, which turns with the pilot mill. Spud the

mill gently to break up the ring and position it for

milling.

• If the milling rate stops or drastically slows down in the

milling of wash pipe, casing or liner without a

noticeable increase in torque, the fish may be turning.

• If so, pull the mill, and retrieve the fish with a spear.

liner hangers, liners, drill pipe, drill collars, wash pipe, or

perforated liners.

Using Pilot Mills:

• Select a pilot mill with a blade O.D. ¼ inch larger than

the O.D. of the tool joint or coupling of the fish milled.

The pilot O.D. should be the same as the drift I.D. of the

fish.

• Determine the best rotary speed and weight to run a pilot

mill for each job. Conditions may change from one pilot

milling job to the next in the same well. The change may

require different rotary speeds and weights at different times. In the absence of experience, start with a speed of

between 80 and 100 RPM’s and a tool weight of 2,000

to 6,000 lbs. Vary the speed and weight to obtain the

best results.

• If milling a liner or casing that is gun-perforated,

damaged with a spear, or collapsed, use 60 RPM’s and

2,000 lbs. of weight or less.

• A sudden drop in the milling rate while milling swaged

casing may be caused by a loose ring of steel formed at

a joint or weld, which turns with the pilot mill. Spud the

mill gently to break up the ring and position it for

milling.

• If the milling rate stops or drastically slows down in the

milling of wash pipe, casing or liner without a

noticeable increase in torque, the fish may be turning.

• If so, pull the mill, and retrieve the fish with a spear.

6- Tapered Mills

The Weatherford Standard Tapered Mill is designed for milling

through restrictions. The spiral blades and pointed nose dressed

with crushed tungsten carbide make the mill ideal for reaming

collapsed casing and liners, cleaning permanent whipstock

windows, milling through jagged or split guide shies, and

enlarging restrictions through retainers and adapters. The torque

encountered governs the tapered mill rotary speeds.

• To overcome torque challenges, do not exceed 75

RPM’s.

• Do not rotate a tapered mill resting on a fish. Enter the

fish with a rotary speed of 75 RPM’s ort less.

• Use less weight when running a tapered mill than a junk

or pilot mill. After entering the fish, increase the tool

weight to slowly to 1,000 to 2,000 lbs. Watch for any

torque increase.

through restrictions. The spiral blades and pointed nose dressed

with crushed tungsten carbide make the mill ideal for reaming

collapsed casing and liners, cleaning permanent whipstock

windows, milling through jagged or split guide shies, and

enlarging restrictions through retainers and adapters. The torque

encountered governs the tapered mill rotary speeds.

• To overcome torque challenges, do not exceed 75

RPM’s.

• Do not rotate a tapered mill resting on a fish. Enter the

fish with a rotary speed of 75 RPM’s ort less.

• Use less weight when running a tapered mill than a junk

or pilot mill. After entering the fish, increase the tool

weight to slowly to 1,000 to 2,000 lbs. Watch for any

torque increase.

7- Watermelon/String Mills

The Weatherford string mill is dressed with tungsten carbide

spiral blades tapered from top to bottom to enable reaming both

up and down in collapsed casing and liners. The lower

connection enables a stinger to be run below the tool to prevent

sidetracking. The mill can also be placed anywhere in a drill or

fishing string. The mill features crushed tungsten carbidedressed

reamer blades.

Can be used for:

• Smooth or rough OD

• Milling out collapsed areas in casing and liners

• Eliminating key seats and doglegs in open hole

• Extending whip stock windows

spiral blades tapered from top to bottom to enable reaming both

up and down in collapsed casing and liners. The lower

connection enables a stinger to be run below the tool to prevent

sidetracking. The mill can also be placed anywhere in a drill or

fishing string. The mill features crushed tungsten carbidedressed

reamer blades.

Can be used for:

• Smooth or rough OD

• Milling out collapsed areas in casing and liners

• Eliminating key seats and doglegs in open hole

• Extending whip stock windows

8- Flat Bottom Cone Buster

Mill

Mill

This flat bottom cone buster mill is dressed with crushed

tungsten carbide and is a very aggressive mill used to mill up bit

cones or other pieces of junk. The mill is sturdy enough for

light spudding on the junk to break it up into smaller pieces.

Large circulation ports improve mud circulation for cooling and

for the removal of cuttings. Field reports show these long

lasting mills are safer than using a rock bit because you can’t

lose any bit cones in the hole. Weatherford’s junk mills work

well when milling drillable packers, bridge plugs, retainers, and

cement.

Note: Important characteristics of cone buster mills include that

they can be furnished with:

tungsten carbide and is a very aggressive mill used to mill up bit

cones or other pieces of junk. The mill is sturdy enough for

light spudding on the junk to break it up into smaller pieces.

Large circulation ports improve mud circulation for cooling and

for the removal of cuttings. Field reports show these long

lasting mills are safer than using a rock bit because you can’t

lose any bit cones in the hole. Weatherford’s junk mills work

well when milling drillable packers, bridge plugs, retainers, and

cement.

Note: Important characteristics of cone buster mills include that

they can be furnished with:

- large circulation ports which improve mud circulation for

- smooth outside diameter along with stabilizer pads designed

9- Cement Mills

Can be used for:

• Milling cement

• Milling cement