THERMAL RECOVERY

Thermal recovery comprises the techniques of :

-Steam flooding.

-Cyclic steam stimulation.

In situ combustion

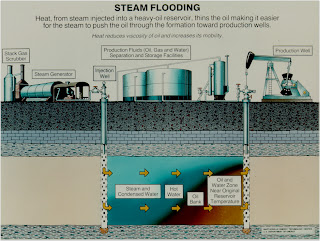

STEAM FLOODING

Recovery by steam flooding is commonly used in

heavy-oil reservoirs containing oil whose high

viscosity is a limiting factor for achieving commercial

oil-producing rates

Procedure:

High-temperature steam is continuously injected into

a reservoir. As the steam loses heat to the formation,

it condenses into hot water, which, coupled with

the continuous supply of steam behind it, provides the

drive to move the oil to production wells

As the formation heats oil, recovery is increased by:

1.The heated oil becomes less viscous, making it easier to move through the formation toward production wells.

2.Expansion or swelling of the oil aids in releasing it from the reservoir rock.

3.Lighter fractions of the oil tend to vaporize, and as they move ahead into the cooler formation ahead of the steam they condense and form a solvent or miscible bank.

4.Finally, the condensed steam cools as it moves through the reservoir and results in what amounts to an ordinary Water flood ahead of the heated zone.

CYCLIC STEAM STIMULATION

("Huff-and-Puff')

(A well-stimulation method)

This method is sometimes applied to heavy-oil reservoirs to boost recovery during the primary production phase.

Procedure:

A predetermined amount of steam is injected into wells that have been drilled or converted for injection purposes. These wells are then shut in to allow the steam to heat or "soak" the producing formation around the well.

- After a sufficient time has elapsed to allow adequate heating, the injection wells are back in production until the heat is dissipated with the produced fluids.

This cycle of soak-and-produce, or "huff-and-puff," may be repeated until the response becomes marginal because of declining natural reservoir pressure and increased water production.

-At this time a continuous steam flood is usually initiated to continue the heating and thinning of the oil and to replace declining reservoir pressure so that production may continue.

-When the steam flooding is started, some of the original injection wells will be converted for use as production wells, along with the others drilled or designated for that purpose.

Oilfield Steam Generator

Insulated Steam Injection Tubing:

The Thermal Tube 3-H tubulars employs a high vacuum as the insulating medium offering the highest thermal performance for oil field steam injection projects

IN SITU COMBUSTION or "Fireflooding

This method is sometimes applied to reservoirs containing oil too viscous or "heavy" to be produced by conventional means.

Burning some of the oil in situ (in place), creates a combustion zone that moves through the formation toward production wells, providing a steam drive and an intense gas drive for the recovery of oil.

Procedure:

This process is sometimes started by lowering a heater or ignitor into an injection well. Air is then injected down the well, and the heater is operated until ignition is accomplished.

-After heating the surrounding rock, the heater is withdrawn, but air injection is continued to maintain the advancing combustion front.

-Water is sometimes injected simultaneously or alternately with air, creating steam which contributes to better heat utilization and reduced air requirements.

Notice in the accompanying illustration that the lighter steam vapors and combustion gases tend to rise into the upper portion of the producing zone, lessening the effectiveness of this method. Injection of water alternately or simultaneously with air can lessen the detrimental overriding effect.

No comments:

Post a Comment