absorber

A tower or column that provides contact between natural gas being processed and a liquid solvent.

absorption

The operation in which one or more components in the gas phase are transferred to (absorbed into) a liquid solvent.

absorption factor

A factor which is an indication of the tendency for a given gas phase component to be transferred to the liquid solvent. It is generally expressed as A = L/KV where L and V are the molar flows of liquid and vapor, and K is the average value of the vapor-liquid equilibrium constant for the component of concern.

absorption oil

A hydrocarbon liquid used to absorb and recover components from the natural gas being processed.

acid gas

The hydrogen sulfide and/or carbon dioxide contained in, or extracted from, gas or other streams.

adiabatic expansion

The expansion of a gas, vapor, or liquid stream from a higher pressure to a lower pressure in which there is no heat transfer between the gas, vapor, or liquid and the surroundings.

adsorbent

A solid substance used to remove components from natural gas being processed.

adsorption

The process by which gaseous components are adsorbed on solids because of their molecular attraction to the solid surface.

amine (alkanolamine)

Any of several liquid compounds containing amino nitrogen generally used in water solution to remove, by reversible chemical reaction, hydrogen sulfide and/or carbon dioxide from gas and liquid hydrocarbon streams.

API Gravity

An arbitrary scale expressing the relative density of liquid petroleum products. The scale is calibrated in degrees API, calculated by the following formula:

γ = relative density

associated gas

Gaseous hydrocarbons occuring as a free-gas phase under original oil-reservoir conditions of temperature and pressure.

atmospheric pressure

The pressure exerted on the earth by the earth’s atmosphere. A pressure of 760 mm of mercury, 29.92 inches of mercury, or 14.696 psia is used as a standard for some measurements. State regulatory bodies have set other standards for use in

measuring the legal volume of gas. Atmospheric pressure may also refer to the absolute ambient pressure at any given location.

barrel

A common English-unit mesure of liquid volume which, in the petroleum industry, equals 42 U.S. liquid gallons for petroleum or natural gas liquid products measured at 60°F and equilibrium vapor pressure. One barrel equals 0.159 cubic meters, or 6.29 barrels per cubic meter .

blanket gas

A gas phase maintained in a vessel containing liquid to protect the liquid against air contamination, to reduce the hazard of explosion, or to maintain pressure of the liquid. The source of the gas is external to the vessel.

blow case

A small vessel in which liquid is accumulated and then forced from the vessel by applying gas or air pressure above the liquid level.

blowdown

The act of emptying or depressuring a vessel. This may also refer to discarded material, such as blowdown water from a boiler or cooling tower.

boilaway test

Sometimes used to describe the GPA weathering test for LPgas. Refer to definition for "weathering test".

bottoms

The liquid or residual matter which is withdrawn from the bottom of a fractionator or other vessel during processing or while in storage.

B-P mix

A liquefied hydrocarbon product composed chiefly of butanes and propane. If it originates in a refinery, it may also contain butylenes and propylene. More specifically, it conforms to the GPA specifications for commercial B-P mixes as described in GPA Standard 2140.

breathing

The movement of vapor in or out of an atmospheric pressure storage tank because of a change of level of the stored liquid, a change in the temperature of the vapor space above the liquid, or a change of atmospheric pressure.

bs&w (basic sediment and water)

Waste that collects in the bottom of vessels and tanks containing petroleum or petroleum products.

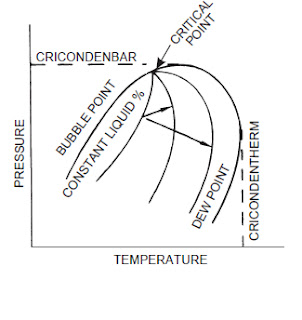

bubble point

The temperature at a specified pressure at which the first stable vapor forms above a liquid.

butane, commercial

A liquefied hydrocarbon consisting predominately of butane and/or butylene and which conforms to the GPA specification for commercial butane defined in GPA Standard 2140.

butane, normal

In commercial transactions, a product meeting the GPA specifications for commercial butane and, in addition, containing a minimum of 95 liquid volume percent normal butane. Chemically, normal butane is an aliphatic compound of the paraffin series having the chemical formula C4H10 and having all of its carbon atoms joined in a straight chain.

calorimeter

An apparatus which is used to determine the heating value of a combustible material.

carbonyl sulfide

A chemical compound of the aldehyde group containing a carbonyl group and sulfur (COS). Sometimes a contaminant in natural gas and NGL. It may need to be removed in order to meet sulfur specifications.

casinghead gas

Unprocessed natural gas produced from a reservoir containing oil. It contains heavier hydrocarbon vapors and is usually produced under low pressure from a casing head on the well.

charcoal test

A test standardized by the Gas Processors Association and the American Gas Association for determining the natural gasoline content of a given natural gas. The gasoline is adsorbed from the gas on activated charcoal and then recovered by distillation.

The test is prescribed in Testing Code 101-43, a joint publication of AGA and GPA.

chromatography

A technique for separating a mixture into individual components by repeated adsorption and desorption on a confined solid bed. It is used for analysis of natural gas and NGL.

Claus Process

A process to convert hydrogen sulfide into elemental sulfur by selective oxidation.

compressibility factor

A factor, usually expressed as "Z," which gives the ratio of the actual volume of gas at a given temperature and pressure to the volume of gas when calculated by the ideal gas law.

compression ratio

The ratio of the absolute discharge pressure from a compressor to the absolute intake pressure. Also applies to one cylinder of a reciprocating compressor and one or more stages of a rotating compressor.

condensate

The liquid formed by the condensation of a vapor or gas; specifically, the hydrocarbon liquid separated from natural gas because of changes in temperature and pressure when the gas

from the reservoir was delivered to the surface separators. In a steam system it may be water that is condensed and returned to the boilers.

convergence pressure

The pressure at a given temperature for a hydrocarbon system of fixed composition at which the vapor-liquid equilibrium Kvalues of the various components in the system become, or

tend to become, unity. The convergence pressure is used to adjust vapor-liquid equilibrium K-values to the particular system under consideration. (See TP-22)

copper strip test

A test using a small strip of pure copper to determine qualitatively the hydrogen sulfide corrosivity of a product. Refer to GPA LP-gas copper strip test (Copper Strip Method), ASTM D-1838 test procedure.

cricondenbar

The highest pressure at which liquid and vapor phases can exist at equilibrium in a multicomponent system.

cricondentherm

The highest temperature at which liquid and vapor phases can exist at equilibrium in a multicomponent system.

critical density

The density of a substance at its critical temperature and critical pressure.

critical pressure

The vapor pressure of a substance at its critical temperature. critical temperature

For a pure component, the maximum temperature at which the component can exist as a liquid.

cryogenic plant

A gas processing plant which is capable of producing natural gas liquid products, including ethane, at very low operating temperatures, usually below minus 50°F.

cubic meter

A unit of volume measurement commonly used in international commerce for petroleum, petroleum products and natural gas. One cubic meter measured at 60°F = 264.172 U.S.

gallons = 6.29 barrels = 35.315 cubic feet measured at 60°F.

deaerator

An item of equipment used for removing air or other non-condensible gases from a process stream or from steam condensate or boiler feed water.

debutanizer

A fractionator designed to separate butane (and more volatile

components if present) from a hydrocarbon mixture.

dehydration

The act or process of removing water from gases or liquids.

demethanized product

A product from which essentially all methane and lighter materials

have been removed.

demethanizer

A fractionator designed to separate methane (and more volatile

components if present) from a hydrocarbon mixture.

depropanizer

A fractionator designed to separate propane (and more volatile

components if present) from a hydrocarbon mixture.

desiccant

A substance used in a dehydrator to remove water and moisture.

Also a material used to remove moisture from the air.

desulfurization

A process by which sulfur and sulfur compounds are removed

from gases or liquid hydrocarbon mixtures.

dew point

The temperature at any given pressure, or the pressure at any

given temperature, at which liquid initially condenses from a

gas or vapor. It is specifically applied to the temperature at

which water vapor starts to condense from a gas mixture

(water dew point), or at which hydrocarbons start to condense

(hydrocarbon dew point).

distillation

The process of separating materials by successively heating to

vaporize a portion and then cooling to liquefy a part of the

vapor. Materials to be separated must differ in boiling point

and/or relative volatility..

doctor test

A qualitative method for detecting hydrogen sulfide and mercaptans

in NGL. The test distinguishes between "sour" and

"sweet" products.

dry gas

(1) Gas whose water content has been reduced by a dehydration

process. (2) Gas containing little or no hydrocarbons commercially

recoverable as liquid product. Gas in this second

definition preferably should be called lean gas.

end point

The maximum temperature observed on the thermometer

during an ASTM distillation test.

EP-mix (ethane-propane mix)

A product consisting of a mixture of essentially ethane and

propane.

expansion turbine

A device which converts part of the energy content of a gas or

liquid stream into mechanical work by expanding the gas or

liquid through a turbine from which work is extracted.

extraction

The process of transferring one or more components from one

liquid phase to another by virtue of different solubility in the

two liquids. It is also used to indicate removal of one or more

constituents from a stream.

field separator

A vessel in the oil or gas field for separating gas, hydrocarbon

liquid, and water from each other.

flash point

The lowest temperature at which vapors from a hydrocarbon

liquid will ignite. See ASTM D-56.

fractionation

See definition of "distillation." Generally used to describe

separation of a mixture of hydrocarbons into individual products

based on difference in boiling point and/or relative volatility.

freeze valve

A specially constructed and calibrated valve designed and

used solely for determining the water content in propane product.

See ASTM D-2713.

gas constant (R)

The constant multiplier in the Ideal Gas Law. Numerically,

R=PV/T, if V is the volume of one mole of an ideal gas at temperature

T and pressure P.

gas hydrate

Refer to definition of "hydrate".

gas injection

The injection of natural gas into a reservoir to maintain or

increase the reservoir pressure or reduce the rate of decline of

the reservoir pressure.

gas lift

A method for bringing crude oil or water to the surface by

injecting gas into the producing well bore.

gas-oil ratio (GOR)

The ratio of gas to liquid hydrocarbon produced from a well.

This may be expressed as standard cubic feet of gas per barrel

of stock tank liquid.

gas processing

The separation of constituents from natural gas for the purpose

of making salable products and also for treating the residue

gas to meet required specifications.

gas processing plant

A plant which processes natural gas for recovery of natural

gas liquids and sometimes other substances such as sulfur.

gas-well gas

The gas produced or separated at surface conditions from the

full well stream produced from a gas reservoir.

gas-well liquids

The liquid separated at surface conditions from the full well

stream produced from a gas reservoir.

gathering system

The network of pipelines which carry gas from the wells to the

processing plant or other separation equipment.

gpm/GPM

(1) gpm (gallons per minute): The term used to describe the

rate of flowing fluid in gallons per minute. (2) GPM — Preferably

Gal/Mcf (gallons per thousand cubic feet): This term refers

to the content in natural gas of components which are

recoverable or recovered as liquid products.

heat medium (heating medium)

A material, whether flowing or static, used to transport heat

from a primary source such as combustion of fuel to another

material. Heating oil, steam, and an eutectic salt mixture are

examples of heat mediums.

heating value (heat of combustion)

The amount of heat obtained by the complete combustion of a

unit quantity of material. The gross, or higher, heating value

is the amount of heat obtained when the water produced in

the combustion is condensed. The net, or lower, heating value

is the amount of heat obtained when the water produced in

the combustion is not condensed.

heavy ends

The portion of a hydrocarbon mixture having the highest boiling

point. Usually hexanes or heptanes and all heavier hydrocarbons

are the heavy ends in a natural gas stream.

hexanes plus (or heptanes plus)

The portion of a hydrocarbon fluid mixture or the last component

of a hydrocarbon analysis which contains the hexanes (or

heptanes) and all hydrocarbons heavier than the hexanes (or

heptanes).

hydrate

A solid material resulting from the combination of a hydrocarbon

with water under pressure.

immiscible

Liquids that will not mix nor blend to give homogeneity are

said to be immiscible.

ideal gas (also called "perfect" gas)

A gas that obeys the ideal gas law expressed as PV=RT, see

Fig. 1-4.

inerts

Elements or compounds not acted upon chemically by the surrounding

environment. Nitrogen and helium are examples of

inert constituents of natural gases.

isobutane

In commercial transactions, a product meeting the GPA specification

for commercial butane and, in addition, containing a

minimum of 95 liquid volume percent isobutane. Chemically,

a hydrocarbon of the paraffin series with the formula C4H10

and having its carbon atoms branched.

jacket water

Water which fills, or is circulated through, a casing which partially

or wholly surrounds a vessel or machine element in order

to remove, add, or distribute heat in order to control the temperature

within the vessel or element.

Joule-Thomson effect

The change in gas temperature which occurs when the gas is

expanded at constant enthalpy from a higher pressure to a

lower pressure. The effect for most gases at normal pressure,

except hydrogen and helium, is a cooling of the gas.

lead acetate test

A method for detecting the presence of hydrogen sulfide by

discoloration of paper which has been moistened with lead acetate

solution. See ASTM D-2420.

lean gas

(1) The residue gas remaining after recovery of natural gas

liquids in a gas processing plant. (2) Unprocessed gas containing

little or no recoverable natural gas liquids.

lean oil

Absorption oil as purchased or recovered by the plant, or oil

from which the absorbed constituents have been removed.

lift gas

Gas used in a gas lift operation.

light ends

The low-boiling, easily evaporated components of a hydrocarbon

liquid mixture.

light hydrocarbons

The low molecular weight hydrocarbons such as methane, ethane,

propane and butanes.

LNG (liquefied natural gas)

The light hydrocarbon portion of natural gas, predominately

methane, which has been liquefied.

loading rack

A structural and piping installation alongside a railroad track

or roadway used for the purpose of filling railroad tank cars

or transport trucks.

LPG (liquefied petroleum gas)

Refer to definition of "LP-gas".

LP-gas (liquefied petroleum gas)

Predominately propane or butane, either separately or in mixtures, which is maintained in a liquid state under pressure within the confining vessel.

LRG (liquefied refinery gas)

Liquid propane or butane produced by a crude oil refinery. It may differ from LP-gas in that propylene and butylene may be present.

LTX (low temperature extraction unit)

A unit which uses the cooling of a constant enthalpy expansion to increase liquid recovery from streams produced from high pressure gas condensate reservoirs. Also called LTS (low temperature separation) unit.

Mcf

An abbreviation for one thousand cubic feet of gas.

MMcf

An abbreviation for one million cubic feet of gas.

mercaptan

Any of a homologous series of compounds of the general formula RSH. All mercaptans possess a foul odor.

miscible flood

A method of secondary recovery of fluids from a reservoir by

injection of fluids that are miscible with the reservoir fluids.

A tower or column that provides contact between natural gas being processed and a liquid solvent.

absorption

The operation in which one or more components in the gas phase are transferred to (absorbed into) a liquid solvent.

absorption factor

A factor which is an indication of the tendency for a given gas phase component to be transferred to the liquid solvent. It is generally expressed as A = L/KV where L and V are the molar flows of liquid and vapor, and K is the average value of the vapor-liquid equilibrium constant for the component of concern.

absorption oil

A hydrocarbon liquid used to absorb and recover components from the natural gas being processed.

acid gas

The hydrogen sulfide and/or carbon dioxide contained in, or extracted from, gas or other streams.

adiabatic expansion

The expansion of a gas, vapor, or liquid stream from a higher pressure to a lower pressure in which there is no heat transfer between the gas, vapor, or liquid and the surroundings.

adsorbent

A solid substance used to remove components from natural gas being processed.

adsorption

The process by which gaseous components are adsorbed on solids because of their molecular attraction to the solid surface.

amine (alkanolamine)

Any of several liquid compounds containing amino nitrogen generally used in water solution to remove, by reversible chemical reaction, hydrogen sulfide and/or carbon dioxide from gas and liquid hydrocarbon streams.

API Gravity

An arbitrary scale expressing the relative density of liquid petroleum products. The scale is calibrated in degrees API, calculated by the following formula:

γ = relative density

associated gas

Gaseous hydrocarbons occuring as a free-gas phase under original oil-reservoir conditions of temperature and pressure.

atmospheric pressure

The pressure exerted on the earth by the earth’s atmosphere. A pressure of 760 mm of mercury, 29.92 inches of mercury, or 14.696 psia is used as a standard for some measurements. State regulatory bodies have set other standards for use in

measuring the legal volume of gas. Atmospheric pressure may also refer to the absolute ambient pressure at any given location.

barrel

A common English-unit mesure of liquid volume which, in the petroleum industry, equals 42 U.S. liquid gallons for petroleum or natural gas liquid products measured at 60°F and equilibrium vapor pressure. One barrel equals 0.159 cubic meters, or 6.29 barrels per cubic meter .

blanket gas

A gas phase maintained in a vessel containing liquid to protect the liquid against air contamination, to reduce the hazard of explosion, or to maintain pressure of the liquid. The source of the gas is external to the vessel.

blow case

A small vessel in which liquid is accumulated and then forced from the vessel by applying gas or air pressure above the liquid level.

blowdown

The act of emptying or depressuring a vessel. This may also refer to discarded material, such as blowdown water from a boiler or cooling tower.

boilaway test

Sometimes used to describe the GPA weathering test for LPgas. Refer to definition for "weathering test".

bottoms

The liquid or residual matter which is withdrawn from the bottom of a fractionator or other vessel during processing or while in storage.

B-P mix

A liquefied hydrocarbon product composed chiefly of butanes and propane. If it originates in a refinery, it may also contain butylenes and propylene. More specifically, it conforms to the GPA specifications for commercial B-P mixes as described in GPA Standard 2140.

breathing

The movement of vapor in or out of an atmospheric pressure storage tank because of a change of level of the stored liquid, a change in the temperature of the vapor space above the liquid, or a change of atmospheric pressure.

bs&w (basic sediment and water)

Waste that collects in the bottom of vessels and tanks containing petroleum or petroleum products.

bubble point

The temperature at a specified pressure at which the first stable vapor forms above a liquid.

butane, commercial

A liquefied hydrocarbon consisting predominately of butane and/or butylene and which conforms to the GPA specification for commercial butane defined in GPA Standard 2140.

butane, normal

In commercial transactions, a product meeting the GPA specifications for commercial butane and, in addition, containing a minimum of 95 liquid volume percent normal butane. Chemically, normal butane is an aliphatic compound of the paraffin series having the chemical formula C4H10 and having all of its carbon atoms joined in a straight chain.

calorimeter

An apparatus which is used to determine the heating value of a combustible material.

carbonyl sulfide

A chemical compound of the aldehyde group containing a carbonyl group and sulfur (COS). Sometimes a contaminant in natural gas and NGL. It may need to be removed in order to meet sulfur specifications.

casinghead gas

Unprocessed natural gas produced from a reservoir containing oil. It contains heavier hydrocarbon vapors and is usually produced under low pressure from a casing head on the well.

charcoal test

A test standardized by the Gas Processors Association and the American Gas Association for determining the natural gasoline content of a given natural gas. The gasoline is adsorbed from the gas on activated charcoal and then recovered by distillation.

The test is prescribed in Testing Code 101-43, a joint publication of AGA and GPA.

chromatography

A technique for separating a mixture into individual components by repeated adsorption and desorption on a confined solid bed. It is used for analysis of natural gas and NGL.

Claus Process

A process to convert hydrogen sulfide into elemental sulfur by selective oxidation.

compressibility factor

A factor, usually expressed as "Z," which gives the ratio of the actual volume of gas at a given temperature and pressure to the volume of gas when calculated by the ideal gas law.

compression ratio

The ratio of the absolute discharge pressure from a compressor to the absolute intake pressure. Also applies to one cylinder of a reciprocating compressor and one or more stages of a rotating compressor.

condensate

The liquid formed by the condensation of a vapor or gas; specifically, the hydrocarbon liquid separated from natural gas because of changes in temperature and pressure when the gas

from the reservoir was delivered to the surface separators. In a steam system it may be water that is condensed and returned to the boilers.

convergence pressure

The pressure at a given temperature for a hydrocarbon system of fixed composition at which the vapor-liquid equilibrium Kvalues of the various components in the system become, or

tend to become, unity. The convergence pressure is used to adjust vapor-liquid equilibrium K-values to the particular system under consideration. (See TP-22)

copper strip test

A test using a small strip of pure copper to determine qualitatively the hydrogen sulfide corrosivity of a product. Refer to GPA LP-gas copper strip test (Copper Strip Method), ASTM D-1838 test procedure.

cricondenbar

The highest pressure at which liquid and vapor phases can exist at equilibrium in a multicomponent system.

cricondentherm

The highest temperature at which liquid and vapor phases can exist at equilibrium in a multicomponent system.

critical density

The density of a substance at its critical temperature and critical pressure.

critical pressure

The vapor pressure of a substance at its critical temperature. critical temperature

For a pure component, the maximum temperature at which the component can exist as a liquid.

cryogenic plant

A gas processing plant which is capable of producing natural gas liquid products, including ethane, at very low operating temperatures, usually below minus 50°F.

cubic meter

A unit of volume measurement commonly used in international commerce for petroleum, petroleum products and natural gas. One cubic meter measured at 60°F = 264.172 U.S.

gallons = 6.29 barrels = 35.315 cubic feet measured at 60°F.

deaerator

An item of equipment used for removing air or other non-condensible gases from a process stream or from steam condensate or boiler feed water.

debutanizer

A fractionator designed to separate butane (and more volatile

components if present) from a hydrocarbon mixture.

dehydration

The act or process of removing water from gases or liquids.

demethanized product

A product from which essentially all methane and lighter materials

have been removed.

demethanizer

A fractionator designed to separate methane (and more volatile

components if present) from a hydrocarbon mixture.

depropanizer

A fractionator designed to separate propane (and more volatile

components if present) from a hydrocarbon mixture.

desiccant

A substance used in a dehydrator to remove water and moisture.

Also a material used to remove moisture from the air.

desulfurization

A process by which sulfur and sulfur compounds are removed

from gases or liquid hydrocarbon mixtures.

dew point

The temperature at any given pressure, or the pressure at any

given temperature, at which liquid initially condenses from a

gas or vapor. It is specifically applied to the temperature at

which water vapor starts to condense from a gas mixture

(water dew point), or at which hydrocarbons start to condense

(hydrocarbon dew point).

distillation

The process of separating materials by successively heating to

vaporize a portion and then cooling to liquefy a part of the

vapor. Materials to be separated must differ in boiling point

and/or relative volatility..

doctor test

A qualitative method for detecting hydrogen sulfide and mercaptans

in NGL. The test distinguishes between "sour" and

"sweet" products.

dry gas

(1) Gas whose water content has been reduced by a dehydration

process. (2) Gas containing little or no hydrocarbons commercially

recoverable as liquid product. Gas in this second

definition preferably should be called lean gas.

end point

The maximum temperature observed on the thermometer

during an ASTM distillation test.

EP-mix (ethane-propane mix)

A product consisting of a mixture of essentially ethane and

propane.

expansion turbine

A device which converts part of the energy content of a gas or

liquid stream into mechanical work by expanding the gas or

liquid through a turbine from which work is extracted.

extraction

The process of transferring one or more components from one

liquid phase to another by virtue of different solubility in the

two liquids. It is also used to indicate removal of one or more

constituents from a stream.

field separator

A vessel in the oil or gas field for separating gas, hydrocarbon

liquid, and water from each other.

flash point

The lowest temperature at which vapors from a hydrocarbon

liquid will ignite. See ASTM D-56.

fractionation

See definition of "distillation." Generally used to describe

separation of a mixture of hydrocarbons into individual products

based on difference in boiling point and/or relative volatility.

freeze valve

A specially constructed and calibrated valve designed and

used solely for determining the water content in propane product.

See ASTM D-2713.

gas constant (R)

The constant multiplier in the Ideal Gas Law. Numerically,

R=PV/T, if V is the volume of one mole of an ideal gas at temperature

T and pressure P.

gas hydrate

Refer to definition of "hydrate".

gas injection

The injection of natural gas into a reservoir to maintain or

increase the reservoir pressure or reduce the rate of decline of

the reservoir pressure.

gas lift

A method for bringing crude oil or water to the surface by

injecting gas into the producing well bore.

gas-oil ratio (GOR)

The ratio of gas to liquid hydrocarbon produced from a well.

This may be expressed as standard cubic feet of gas per barrel

of stock tank liquid.

gas processing

The separation of constituents from natural gas for the purpose

of making salable products and also for treating the residue

gas to meet required specifications.

gas processing plant

A plant which processes natural gas for recovery of natural

gas liquids and sometimes other substances such as sulfur.

gas-well gas

The gas produced or separated at surface conditions from the

full well stream produced from a gas reservoir.

gas-well liquids

The liquid separated at surface conditions from the full well

stream produced from a gas reservoir.

gathering system

The network of pipelines which carry gas from the wells to the

processing plant or other separation equipment.

gpm/GPM

(1) gpm (gallons per minute): The term used to describe the

rate of flowing fluid in gallons per minute. (2) GPM — Preferably

Gal/Mcf (gallons per thousand cubic feet): This term refers

to the content in natural gas of components which are

recoverable or recovered as liquid products.

heat medium (heating medium)

A material, whether flowing or static, used to transport heat

from a primary source such as combustion of fuel to another

material. Heating oil, steam, and an eutectic salt mixture are

examples of heat mediums.

heating value (heat of combustion)

The amount of heat obtained by the complete combustion of a

unit quantity of material. The gross, or higher, heating value

is the amount of heat obtained when the water produced in

the combustion is condensed. The net, or lower, heating value

is the amount of heat obtained when the water produced in

the combustion is not condensed.

heavy ends

The portion of a hydrocarbon mixture having the highest boiling

point. Usually hexanes or heptanes and all heavier hydrocarbons

are the heavy ends in a natural gas stream.

hexanes plus (or heptanes plus)

The portion of a hydrocarbon fluid mixture or the last component

of a hydrocarbon analysis which contains the hexanes (or

heptanes) and all hydrocarbons heavier than the hexanes (or

heptanes).

hydrate

A solid material resulting from the combination of a hydrocarbon

with water under pressure.

immiscible

Liquids that will not mix nor blend to give homogeneity are

said to be immiscible.

ideal gas (also called "perfect" gas)

A gas that obeys the ideal gas law expressed as PV=RT, see

Fig. 1-4.

inerts

Elements or compounds not acted upon chemically by the surrounding

environment. Nitrogen and helium are examples of

inert constituents of natural gases.

isobutane

In commercial transactions, a product meeting the GPA specification

for commercial butane and, in addition, containing a

minimum of 95 liquid volume percent isobutane. Chemically,

a hydrocarbon of the paraffin series with the formula C4H10

and having its carbon atoms branched.

jacket water

Water which fills, or is circulated through, a casing which partially

or wholly surrounds a vessel or machine element in order

to remove, add, or distribute heat in order to control the temperature

within the vessel or element.

Joule-Thomson effect

The change in gas temperature which occurs when the gas is

expanded at constant enthalpy from a higher pressure to a

lower pressure. The effect for most gases at normal pressure,

except hydrogen and helium, is a cooling of the gas.

lead acetate test

A method for detecting the presence of hydrogen sulfide by

discoloration of paper which has been moistened with lead acetate

solution. See ASTM D-2420.

lean gas

(1) The residue gas remaining after recovery of natural gas

liquids in a gas processing plant. (2) Unprocessed gas containing

little or no recoverable natural gas liquids.

lean oil

Absorption oil as purchased or recovered by the plant, or oil

from which the absorbed constituents have been removed.

lift gas

Gas used in a gas lift operation.

light ends

The low-boiling, easily evaporated components of a hydrocarbon

liquid mixture.

light hydrocarbons

The low molecular weight hydrocarbons such as methane, ethane,

propane and butanes.

LNG (liquefied natural gas)

The light hydrocarbon portion of natural gas, predominately

methane, which has been liquefied.

loading rack

A structural and piping installation alongside a railroad track

or roadway used for the purpose of filling railroad tank cars

or transport trucks.

LPG (liquefied petroleum gas)

Refer to definition of "LP-gas".

LP-gas (liquefied petroleum gas)

Predominately propane or butane, either separately or in mixtures, which is maintained in a liquid state under pressure within the confining vessel.

LRG (liquefied refinery gas)

Liquid propane or butane produced by a crude oil refinery. It may differ from LP-gas in that propylene and butylene may be present.

LTX (low temperature extraction unit)

A unit which uses the cooling of a constant enthalpy expansion to increase liquid recovery from streams produced from high pressure gas condensate reservoirs. Also called LTS (low temperature separation) unit.

Mcf

An abbreviation for one thousand cubic feet of gas.

MMcf

An abbreviation for one million cubic feet of gas.

mercaptan

Any of a homologous series of compounds of the general formula RSH. All mercaptans possess a foul odor.

miscible flood

A method of secondary recovery of fluids from a reservoir by

injection of fluids that are miscible with the reservoir fluids.