Analytical and numerical solutions of simple one-dimensional, one-phase flow equations

As an introduction to reservoir simulation, we will review the simplest one-dimensional flow equations for

horizontal flow of one fluid, and look at analytical and numerical solutions of pressure as function of position

and time. These equations are derived using the continuity equation, Darcy's equation, and compressibility

definitions for rock and fluid, assuming constant permeability and viscosity. They are the simplest equations we

can have, which involve transient fluid flow inside the reservoir.

Linear flow

Consider a simple horizontal slab of porous material, where initially the pressure everywhere is P0 , and then at

time zero, the left side pressure (at x = 0 ) is raised to PL while the right side pressure (at x = L) is kept at

PR = P0 . The system is shown on the next figure:

Partial differential equation (PDE)

The linear, one dimensional, horizontal, one phase, partial differential flow equation for a liquid, assuming

constant permeability, viscosity and compressibility is:

Transient vs. steady state flow

The equation above includes time dependency through the right hand side term. Thus, it can describe transient, or

time dependent flow. If the flow reaches a state where it is no longer time dependent, we denote the flow as steady

state. The equation then simplifies to:

Transient and steady state pressure distributions are illustrated graphically in the figure below for a system where

initial and right hand pressures are equal. As can be observed, for some period of time, depending on the properties

of the system, the pressure will increase in all parts of the system (transient solution), for then to approach a final

distribution (steady state), described by a straight line between the two end pressures.

Analytical solution to the linear PDE

The analytical solution of the transient pressure development in the slab is then given by:

It may be seen from the solution that as time becomes large, the exponential term approaches zero, and the

solution becomes:

This is, of course, the solution to the steady state equation above.

Radial flow (Well test equation)

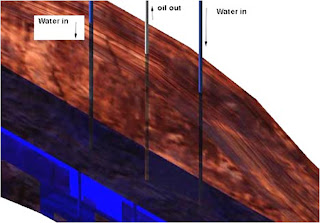

An alternative form of the simple one dimensional, horizontal flow equation for a liquid, is the radial equation that

frequently is used for well test interpretation. In this case the flow area is proportional to r2, as shown in the

following figure:

The one-dimensional (radial) flow equation in this coordinate system becomes

For an infinite reservoir with P(r Æ•) = Pi and well rate q from a well in the center (at r=rw) the analytical

solution s