Downhole Motor

- Turbodrills have been around for many years but are seldom used for directional drilling

- Turbodrills have very high rotary speeds (500 to 1200 rpm)

- Because of the high rpm, bit life is limited

- Diamond and PDC bits are more applicable to turbodrills

- Turbodrills have low starting torque

- If the motor is in a bind, it is hard to get the motor started

- Turbodrills are used in directional drilling where the temperature exceeds the limit of a positive displacement motor

Positive displacement motors were introduced in the 1960’s

Speed (RPM) / Torque (Ft-Lbs.)

- For best performance, the power section should be matched to the bit and formation being drilled. The speed and torque of a power section is directly linked to the number of lobes on the rotor and stator. The higher the number of lobes, the higher the torque and the lower the RPM.

Dump sub

- Not often used

- Allows string to fill or drain when tripping

- Allows low volume circulation in stuck bit situations

Power pack section

Rotor is hard

Stator is flexible

Stator housing is thin

PDM is not a drill collar

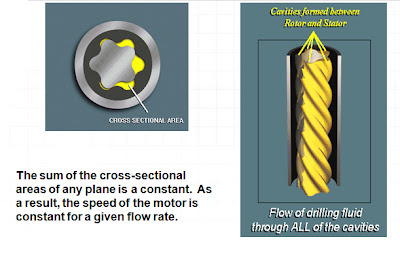

- Reverse application of the Moineau pump principle

- Elastomer lined - steel tube stator

- Chrome coated steel rotor

- Converts Hydraulic HP (flow & pressure) to Mechanical HP (rpm & torque) There are three main producers of motor power sections in the world:

Typical PDM power curve

- Rotor is coupled to transmission

- Transmission shaft is coupled to the bearing pack

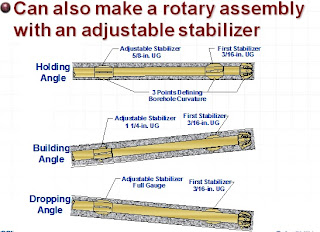

- The adjustable bent housing enables the bend to be changed at the wellsite

- The housing can be adjusted 0.26 to 3.0 degrees depending upon motor size

Bearing function

- On bottom thrust bearings carry force from the bit (WOB)

- Off bottom thrust bearings carry the hydraulic load of the mud and weight of the rotor

- Radial bearings carry side loads

- Flow restrictor diverts a portion of the mud for lubrication