FISHING FOR JUNK

Overview

Any undesirable object that is stuck or accidentally dropped in a well is

referred to as “junk.” Junk may include bit cones, tong dies, broken slips,

reamer parts or debris created by a fishing or milling operation, or any other

small debris that could impede normal drilling operations. Because of the

wide variety of junk that can be in the hole and the likelihood that the

customer may not know what the junk is, you will have to be fairly creative

in planning a junk fishing operation. However, because of the time and

money spent on fishing operations, you will need to devise a method for

fishing the junk that involves the fewest trips and equipment as possible.

referred to as “junk.” Junk may include bit cones, tong dies, broken slips,

reamer parts or debris created by a fishing or milling operation, or any other

small debris that could impede normal drilling operations. Because of the

wide variety of junk that can be in the hole and the likelihood that the

customer may not know what the junk is, you will have to be fairly creative

in planning a junk fishing operation. However, because of the time and

money spent on fishing operations, you will need to devise a method for

fishing the junk that involves the fewest trips and equipment as possible.

Deciding How to Fish Junk

Evaluating the junk

Any debris or junk in the borehole must be thoroughly evaluated before any

successful fishing attempt can be made. Depending on the properties of the

junk, it can either be milled up, recovered, or pushed back (walled-off) into

the formation.

Consider the following questions before proceeding with a fishing job:

successful fishing attempt can be made. Depending on the properties of the

junk, it can either be milled up, recovered, or pushed back (walled-off) into

the formation.

Consider the following questions before proceeding with a fishing job:

- What is the size, weight, and condition of the junk?

- Is the junk magnetic?

- Can the junk be picked up?

- What are the dimensions of the bit cone or cones?

The company man would ideally know exactly what the junk in the hole

consists of. When the nature of the junk is unknown, you must be creative

in your approach to fishing the junk.

consists of. When the nature of the junk is unknown, you must be creative

in your approach to fishing the junk.

Impact of the junk size, weight, and condition

Try to determine the size, weight, and condition of the junk. This

information will help you determine the best method for fishing the junk.

For example, if you have junk that is:

information will help you determine the best method for fishing the junk.

For example, if you have junk that is:

- large and/or irregularly shaped, you might try a poor boy basket

- smaller, you might try a magnet, core type, or reverse circulating basket.

For very large pieces of junk, you may need to use a junk shot to break it

into smaller pieces before attempting to fish.

into smaller pieces before attempting to fish.

Determining if the junk is magnetic

Try to find out what the junk is made of. If it has a high ferrous content, it

is probably magnetic. The easiest method for fishing magnetic junk is using

a magnet.

is probably magnetic. The easiest method for fishing magnetic junk is using

a magnet.

Determining is the junk can be picked up

If the OD of the junk is significantly smaller than the ID of the hole, than

there is a good chance that it can be picked up. However, if the OD of the

junk is fairly large, it will be harder to get a fishing tool over it. In this case,

you will probably have to mill the junk to break it up and collect the pieces

in a boot basket.

there is a good chance that it can be picked up. However, if the OD of the

junk is fairly large, it will be harder to get a fishing tool over it. In this case,

you will probably have to mill the junk to break it up and collect the pieces

in a boot basket.

Determining cone dimensions

If you know the junk is a bit cone, the dimensions of the cone must be

known before deciding which tool to run. Find out the size of the bit from

which the cone was lost, and verify the maximum OD of the cone. Select a

tool that has an ID at least 1/8" larger than the OD of the cone.

For example, a 7 7/8" bit cone is 5 15/64" OD. A 7 1/8" OD Bowen Itco

Type Junk Basket has an ID size of 5 28/64". This tool will get over the bit

cone.

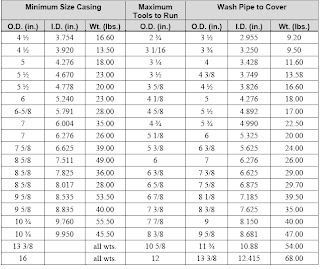

Standard rock bit cone dimensions are shown in Table 2-1. Note: This

information can also be found in the Bowen user manuals.

known before deciding which tool to run. Find out the size of the bit from

which the cone was lost, and verify the maximum OD of the cone. Select a

tool that has an ID at least 1/8" larger than the OD of the cone.

For example, a 7 7/8" bit cone is 5 15/64" OD. A 7 1/8" OD Bowen Itco

Type Junk Basket has an ID size of 5 28/64". This tool will get over the bit

cone.

Standard rock bit cone dimensions are shown in Table 2-1. Note: This

information can also be found in the Bowen user manuals.