1. INTRODUCTION

This chapter covers the most commonly used materials of construction

for piping systems within a process plant.

The two principal international codes used for the design and

construction of a process plant are ASME B31.3, Process Piping, and

the ASME Boiler and Pressure Vessel Code Sections.

Generally, only materials recognized by the American Society of

Mechanical Engineers (ASME) can be used as the ‘‘materials of

construction’’ for piping systems within process plants, because they

meet the requirements set out by a recognized materials testing body, like

the American Society of Testing and Materials (ASTM).

There are exceptions, however; the client or end user must be satisfied

that the non-ASTM materials offered are equal or superior to the ASTM

material specified for the project.

The Unified Numbering System (UNS) for identifying various alloys is

also quoted. This is not a specification, but in most cases, it can be crossreferenced

to a specific ASTM specification.

1.1. American Society of Testing and Materials

The American Society of Testing and Materials specifications

cover materials for many industries, and they are not restricted to the

process sector and associated industries. Therefore, many ASTM

specifications are not relevant to this book and will never be referred to

by the piping engineer.

We include passages from a number of the most commonly used

ASTM specifications. This gives the piping engineer an overview of the

specifications and scope in one book, rather than several ASTM books,

which carry specifications a piping engineer will never use.

It is essential that at the start of a project, the latest copies of all the

relevant codes and standards are available to the piping engineer.

All ASTM specification identifiers carry a prefix followed by a

sequential number and the year of issue; for example, A105/A105M-02,

Standard Specification for Carbon Steel Forgings for Piping Applications,

breaks down as follows:

A ¼ prefix.

105 ¼ sequential number.

M means that this specification carries metric units.

02 ¼ 2002, the year of the latest version.

Official title ¼ Standard Specification for Carbon Steel Forgings for Piping

Applications.

The complete range of ASTM prefixes are A, B, C, D, E, F, G, PS, WK;

however, the piping requirements referenced in ASME B31.3, which is

considered our design ‘‘bible,’’ call for only A, B, C, D, and E.

The requirements of an ASTM specification cover the following:

. Chemical requirements (the significant chemicals used in the production

and the volumes).

. Mechanical requirements (yield, tensile strength, elongation, hardness).

. Method of manufacture.

. Heat treatment.

. Weld repairs.

. Tolerances.

. Certification.

. Markings.

. Supplementary notes.

If a material satisfies an ASTM standard, then the various characteristics

of the material are known and the piping engineer can confidently use the

material in a design, because the allowable stresses and the strength of

the material can be predicted and its resistance against the corrosion

of the process is known.

1.2. Unified Numbering System

Alloy numbering systems vary greatly from one alloy group to the

next. To avoid confusion, the UNS for metals and alloys was developed.

The UNS number is not a specification, because it does not refer to the

method of manufacturing in which the material is supplied (e.g., pipe

bar, forging, casting, plate). The UNS indicates the chemical composition

of the material.

An outline of the organization of UNS designations follows:

In this chapter, the ASTM specification is the most common reference in

the design of process plants. Extracts from a number of the most

commonly used ASTM specifications are listed in the book, along

with the general scope of the specification and the mechanical

requirements.

For detailed information, the complete specification must be referred

to and the engineering company responsible for the design of the plant

must have copies of all codes and standards used as part of their

contractual obligation.

1.3. Manufacturer’s Standards

Several companies are responsible for inventing, developing, and

manufacturing special alloys, which have advanced characteristics that

allow them to be used at elevated temperatures, low temperatures, and in

highly corrosive process services. In many cases, these materials were

developed for the aerospace industry, and after successful application,

they are now used in other sectors.

Three examples of such companies are listed below:

. Haynes International, Inc.—high-performance nickel- and cobalt-based

alloys.

. Carpenter Technology Corporation—stainless steel and titanium.

. Sandvik—special alloys.

1.4. Metallic Material Equivalents

Some ASTM materials are compatible with specifications from other

countries, such as BS (Britain), AFNOR (France), DIN (Germany), and

JIS (Japan). If a specification from one of these other countries either

meets or is superior to the ASTM specification, then it is considered a

suitable alternative, if the project certifications are met.

1.5. Nonmetallic Materials

In many cases, nonmetallic materials have been developed by a major

manufacturer, such as Dow Chemical, ICI, or DuPont, which holds the

patent on the material. This material can officially be supplied only by

the patent owner or a licensed representative.

The patent owners are responsible for material specification, which

defines the chemical composition and associated mechanical characteristics.

Four examples of patented materials that are commonly used in

the process industry are as follows:

. Nylon, a polyamide, DuPont.

. Teflon, polytetrafluoroethylene, DuPont.

. PEEK, polyetheretherketone, ICI.

. Saran, polyvinylidene chloride, Dow.

Certain types of generic nonmetallic material covering may have several

patent owners; for example, patents for PVC (polyvinyl chloride) are

owned by Carina (Shell), Corvic (ICI), Vinoflex (BASF), and many

others. Each of these examples has unique characteristics that fall into

the range covered by the generic term PVC. To be sure of these

characteristics, it is important that a material data sheet (MDS) is

obtained from the manufacturer and this specification forms part of the

project documentation.

2. MATERIALS SPECIFICATIONS

Listed below are extracts from the most commonly used material

specifications referenced in ASME B31.3.

ASTM, A53/A53M-02 (Volume 01.01), Standard

Specification for Pipe, Steel, Black and Hot-

Dipped, Zinc-Coated, Welded and Seamless

Scope.

1.1 This specification covers seamless and welded black and hot-dipped

galvanized steel pipe in NPS 1⁄8 to NPS 26 (DN 6 to DN 650) for the

following types and grades:

1.2.1 Type F—furnace-butt welded, continuous welded Grade A.

1.2.2 Type E—electric-resistance welded, Grades A and B.

1.2.3 Type S—seamless, Grades A and B.

Referenced Documents

ASTM

A90/A90M, Test Method for Weight [Mass] of Coating on Iron and Steel

Articles with Zinc or Zinc-Alloy Coatings.

A370, Test Methods and Definitions for Mechanical Testing of Steel

Products.

A530/A530M, Specification for General Requirements for Specialized

Carbon and Alloy Steel Pipe.

A700, Practices for Packaging, Marking, and Loading Methods for Steel

Products for Domestic Shipment.

A751, Test Methods, Practices, and Terminology for Chemical Analysis of

Steel Products.

A865, Specification for Threaded Couplings, Steel, Black or Zinc-Coated

(Galvanized) Welded or Seamless, for Use in Steel Pipe Joints.

B6, Specification for Zinc.

E29, Practice for Using Significant Digits in Test Data to Determine

Conformance with Specifications.

E213, Practice for Ultrasonic Examination of Metal Pipe and Tubing.

E309, Practice for Eddy-Current Examination of Steel Tubular Products

Using Magnetic Saturation.

E570, Practice for Flux Leakage Examination of Ferromagnetic Steel

Tubular Products.

E1806, Practice for Sampling Steel and Iron for Determination of Chemical

Composition.

ASC Acredited Standards Committee X12.

ASME

B1.20.1, Pipe Threads, General Purpose.

B36.10, Welded and Seamless Wrought Steel Pipe.

Military Standard (MIL)

STD-129, Marking for Shipment and Storage.

STD-163, Steel Mill Products Preparation for Shipment and Storage.

Fed. Std. No. 123, Marking for Shipment (Civil Agencies).

Fed. Std. No. 183, Continuous Identification Marking of Iron and Steel

Products.

American Petroleum Institute (API)

5L, Specification for Line Pipe.

Methods of Manufacture. Open hearth (OH), electrofurnace (EF), basic

oxygen (BO).

Chemical Requirements. Refer to ASTM A53/A53M.

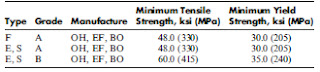

Mechanical Requirements. These are extracted from ASTM A53/A53M:

ASTM, A106-02a (Volume 1.01), Standard

Specification for Seamless Carbon Steel Pipe

for High-Temperature Service

Scope. This specification covers seamless carbon steel pipe for hightemperature

service (Note: It is suggested that consideration be given to

possible graphitization) in NPS 1⁄8 –NPS 48 inclusive, with nominal

(average) wall thickness as given in ANSI B 36.10. It is permissible to

furnish pipe having other dimensions provided such pipe complies with all

other requirements of this specification. Pipe ordered under this

specification is suitable for bending, flanging, and similar forming

operations and for welding.Whenthe steel is to be welded, it is presupposed

that a welding procedure suitable to the grade of steel and intended use or

service is utilized (Note: The purpose for which the pipe is to be used should

be stated in the order. Grade A rather than Grade B or Grade C is the

preferred grade for close coiling or cold bending. This note is not intended

to prohibit the cold bending of Grade B seamless pipe).

Referenced Documents

ASTM

A530/A530M, Specification for General Requirements for Specialized

Carbon and Alloy Steel Pipe.

E213, Practice for Ultrasonic Examination of Metal Pipe and Tubing.

E309, Practice for Eddy-Current Examination of Steel Tubular Products

Using Magnetic Saturation.

E381, Method of Macroetch Testing, Inspection, and Rating Steel Products,

Comprising Bars, Billets, Blooms, and Forgings.

A520, Specification for Supplementary Requirements for Seamless and

Electric-Resistance-Welded Carbon Steel Tubular Products for High-

Temperature Service Conforming to ISO Recommendations for Boiler

Construction.

E570, Practice for Flux Leakage Examination of Ferromagnetic Steel

Tubular Products.

ASME

B36.10, Welded and Seamless Wrought Steel.

Methods of Manufacture. Open hearth (OH), electrofurnace (EF), basic

oxygen (BO).

Chemical Requirements. Refer to from ASTM A106/A106M.

Mechanical Requirements. These are extracted from ASTM A106/

A106M:

ASTM, A126-95 (2001) (Volume 01.02), Standard

Specification for Gray Iron Castings for Valves,

Flanges, and Pipe Fittings

Scope. This specification covers three classes of gray iron for castings

intended for use as valve pressure retaining parts, pipe fittings, and flanges.

Referenced Documents

ASTM

A438, Test Method for Transverse Testing of Gray Cast Iron.

A644, Terminology Relating to Iron Castings.

E8, Test Methods for Tension Testing of Metallic Materials.

A48, Specification for Gray Iron Castings.

Sizes. Varies.

Heat Treatment. Refer to ASTM A126/A126M.

Welding Repair. For repair procedures and welder qualifications, see

ASTM A488/A488M.

Chemical Requirements. Refer to ASTM A126/A126M.

MechanicalRequirements. Theseare extractedfromASTMA126/A126M:

This chapter covers the most commonly used materials of construction

for piping systems within a process plant.

The two principal international codes used for the design and

construction of a process plant are ASME B31.3, Process Piping, and

the ASME Boiler and Pressure Vessel Code Sections.

Generally, only materials recognized by the American Society of

Mechanical Engineers (ASME) can be used as the ‘‘materials of

construction’’ for piping systems within process plants, because they

meet the requirements set out by a recognized materials testing body, like

the American Society of Testing and Materials (ASTM).

There are exceptions, however; the client or end user must be satisfied

that the non-ASTM materials offered are equal or superior to the ASTM

material specified for the project.

The Unified Numbering System (UNS) for identifying various alloys is

also quoted. This is not a specification, but in most cases, it can be crossreferenced

to a specific ASTM specification.

1.1. American Society of Testing and Materials

The American Society of Testing and Materials specifications

cover materials for many industries, and they are not restricted to the

process sector and associated industries. Therefore, many ASTM

specifications are not relevant to this book and will never be referred to

by the piping engineer.

We include passages from a number of the most commonly used

ASTM specifications. This gives the piping engineer an overview of the

specifications and scope in one book, rather than several ASTM books,

which carry specifications a piping engineer will never use.

It is essential that at the start of a project, the latest copies of all the

relevant codes and standards are available to the piping engineer.

All ASTM specification identifiers carry a prefix followed by a

sequential number and the year of issue; for example, A105/A105M-02,

Standard Specification for Carbon Steel Forgings for Piping Applications,

breaks down as follows:

A ¼ prefix.

105 ¼ sequential number.

M means that this specification carries metric units.

02 ¼ 2002, the year of the latest version.

Official title ¼ Standard Specification for Carbon Steel Forgings for Piping

Applications.

The complete range of ASTM prefixes are A, B, C, D, E, F, G, PS, WK;

however, the piping requirements referenced in ASME B31.3, which is

considered our design ‘‘bible,’’ call for only A, B, C, D, and E.

The requirements of an ASTM specification cover the following:

. Chemical requirements (the significant chemicals used in the production

and the volumes).

. Mechanical requirements (yield, tensile strength, elongation, hardness).

. Method of manufacture.

. Heat treatment.

. Weld repairs.

. Tolerances.

. Certification.

. Markings.

. Supplementary notes.

If a material satisfies an ASTM standard, then the various characteristics

of the material are known and the piping engineer can confidently use the

material in a design, because the allowable stresses and the strength of

the material can be predicted and its resistance against the corrosion

of the process is known.

1.2. Unified Numbering System

Alloy numbering systems vary greatly from one alloy group to the

next. To avoid confusion, the UNS for metals and alloys was developed.

The UNS number is not a specification, because it does not refer to the

method of manufacturing in which the material is supplied (e.g., pipe

bar, forging, casting, plate). The UNS indicates the chemical composition

of the material.

An outline of the organization of UNS designations follows:

In this chapter, the ASTM specification is the most common reference in

the design of process plants. Extracts from a number of the most

commonly used ASTM specifications are listed in the book, along

with the general scope of the specification and the mechanical

requirements.

For detailed information, the complete specification must be referred

to and the engineering company responsible for the design of the plant

must have copies of all codes and standards used as part of their

contractual obligation.

1.3. Manufacturer’s Standards

Several companies are responsible for inventing, developing, and

manufacturing special alloys, which have advanced characteristics that

allow them to be used at elevated temperatures, low temperatures, and in

highly corrosive process services. In many cases, these materials were

developed for the aerospace industry, and after successful application,

they are now used in other sectors.

Three examples of such companies are listed below:

. Haynes International, Inc.—high-performance nickel- and cobalt-based

alloys.

. Carpenter Technology Corporation—stainless steel and titanium.

. Sandvik—special alloys.

1.4. Metallic Material Equivalents

Some ASTM materials are compatible with specifications from other

countries, such as BS (Britain), AFNOR (France), DIN (Germany), and

JIS (Japan). If a specification from one of these other countries either

meets or is superior to the ASTM specification, then it is considered a

suitable alternative, if the project certifications are met.

1.5. Nonmetallic Materials

In many cases, nonmetallic materials have been developed by a major

manufacturer, such as Dow Chemical, ICI, or DuPont, which holds the

patent on the material. This material can officially be supplied only by

the patent owner or a licensed representative.

The patent owners are responsible for material specification, which

defines the chemical composition and associated mechanical characteristics.

Four examples of patented materials that are commonly used in

the process industry are as follows:

. Nylon, a polyamide, DuPont.

. Teflon, polytetrafluoroethylene, DuPont.

. PEEK, polyetheretherketone, ICI.

. Saran, polyvinylidene chloride, Dow.

Certain types of generic nonmetallic material covering may have several

patent owners; for example, patents for PVC (polyvinyl chloride) are

owned by Carina (Shell), Corvic (ICI), Vinoflex (BASF), and many

others. Each of these examples has unique characteristics that fall into

the range covered by the generic term PVC. To be sure of these

characteristics, it is important that a material data sheet (MDS) is

obtained from the manufacturer and this specification forms part of the

project documentation.

2. MATERIALS SPECIFICATIONS

Listed below are extracts from the most commonly used material

specifications referenced in ASME B31.3.

ASTM, A53/A53M-02 (Volume 01.01), Standard

Specification for Pipe, Steel, Black and Hot-

Dipped, Zinc-Coated, Welded and Seamless

Scope.

1.1 This specification covers seamless and welded black and hot-dipped

galvanized steel pipe in NPS 1⁄8 to NPS 26 (DN 6 to DN 650) for the

following types and grades:

1.2.1 Type F—furnace-butt welded, continuous welded Grade A.

1.2.2 Type E—electric-resistance welded, Grades A and B.

1.2.3 Type S—seamless, Grades A and B.

Referenced Documents

ASTM

A90/A90M, Test Method for Weight [Mass] of Coating on Iron and Steel

Articles with Zinc or Zinc-Alloy Coatings.

A370, Test Methods and Definitions for Mechanical Testing of Steel

Products.

A530/A530M, Specification for General Requirements for Specialized

Carbon and Alloy Steel Pipe.

A700, Practices for Packaging, Marking, and Loading Methods for Steel

Products for Domestic Shipment.

A751, Test Methods, Practices, and Terminology for Chemical Analysis of

Steel Products.

A865, Specification for Threaded Couplings, Steel, Black or Zinc-Coated

(Galvanized) Welded or Seamless, for Use in Steel Pipe Joints.

B6, Specification for Zinc.

E29, Practice for Using Significant Digits in Test Data to Determine

Conformance with Specifications.

E213, Practice for Ultrasonic Examination of Metal Pipe and Tubing.

E309, Practice for Eddy-Current Examination of Steel Tubular Products

Using Magnetic Saturation.

E570, Practice for Flux Leakage Examination of Ferromagnetic Steel

Tubular Products.

E1806, Practice for Sampling Steel and Iron for Determination of Chemical

Composition.

ASC Acredited Standards Committee X12.

ASME

B1.20.1, Pipe Threads, General Purpose.

B36.10, Welded and Seamless Wrought Steel Pipe.

Military Standard (MIL)

STD-129, Marking for Shipment and Storage.

STD-163, Steel Mill Products Preparation for Shipment and Storage.

Fed. Std. No. 123, Marking for Shipment (Civil Agencies).

Fed. Std. No. 183, Continuous Identification Marking of Iron and Steel

Products.

American Petroleum Institute (API)

5L, Specification for Line Pipe.

Methods of Manufacture. Open hearth (OH), electrofurnace (EF), basic

oxygen (BO).

Chemical Requirements. Refer to ASTM A53/A53M.

Mechanical Requirements. These are extracted from ASTM A53/A53M:

ASTM, A106-02a (Volume 1.01), Standard

Specification for Seamless Carbon Steel Pipe

for High-Temperature Service

Scope. This specification covers seamless carbon steel pipe for hightemperature

service (Note: It is suggested that consideration be given to

possible graphitization) in NPS 1⁄8 –NPS 48 inclusive, with nominal

(average) wall thickness as given in ANSI B 36.10. It is permissible to

furnish pipe having other dimensions provided such pipe complies with all

other requirements of this specification. Pipe ordered under this

specification is suitable for bending, flanging, and similar forming

operations and for welding.Whenthe steel is to be welded, it is presupposed

that a welding procedure suitable to the grade of steel and intended use or

service is utilized (Note: The purpose for which the pipe is to be used should

be stated in the order. Grade A rather than Grade B or Grade C is the

preferred grade for close coiling or cold bending. This note is not intended

to prohibit the cold bending of Grade B seamless pipe).

Referenced Documents

ASTM

A530/A530M, Specification for General Requirements for Specialized

Carbon and Alloy Steel Pipe.

E213, Practice for Ultrasonic Examination of Metal Pipe and Tubing.

E309, Practice for Eddy-Current Examination of Steel Tubular Products

Using Magnetic Saturation.

E381, Method of Macroetch Testing, Inspection, and Rating Steel Products,

Comprising Bars, Billets, Blooms, and Forgings.

A520, Specification for Supplementary Requirements for Seamless and

Electric-Resistance-Welded Carbon Steel Tubular Products for High-

Temperature Service Conforming to ISO Recommendations for Boiler

Construction.

E570, Practice for Flux Leakage Examination of Ferromagnetic Steel

Tubular Products.

ASME

B36.10, Welded and Seamless Wrought Steel.

Methods of Manufacture. Open hearth (OH), electrofurnace (EF), basic

oxygen (BO).

Chemical Requirements. Refer to from ASTM A106/A106M.

Mechanical Requirements. These are extracted from ASTM A106/

A106M:

ASTM, A126-95 (2001) (Volume 01.02), Standard

Specification for Gray Iron Castings for Valves,

Flanges, and Pipe Fittings

Scope. This specification covers three classes of gray iron for castings

intended for use as valve pressure retaining parts, pipe fittings, and flanges.

Referenced Documents

ASTM

A438, Test Method for Transverse Testing of Gray Cast Iron.

A644, Terminology Relating to Iron Castings.

E8, Test Methods for Tension Testing of Metallic Materials.

A48, Specification for Gray Iron Castings.

Sizes. Varies.

Heat Treatment. Refer to ASTM A126/A126M.

Welding Repair. For repair procedures and welder qualifications, see

ASTM A488/A488M.

Chemical Requirements. Refer to ASTM A126/A126M.

MechanicalRequirements. Theseare extractedfromASTMA126/A126M: