Any string of casing whose top is located below the surface, hung inside the previous casing and is run to its setting depth by drill pipe.

Why Liners ?

-Prime reason:

–Save $$

–(Cost of 1 Joint of Casing can be $3,000!)

-Cover Corroded/Damaged Casing

-Cover:

–Lost Circulation Zones.

–Shales or Plastic Formations

–Salt Zones

-Deep Wells:

Rig Unable to Lift Long String of Casing Types of Liners

-Production:

–Most common

–Save $$

–Slotted liner

-Intermediate/drilling:

–Cover problem zone in order to be able to continue drilling

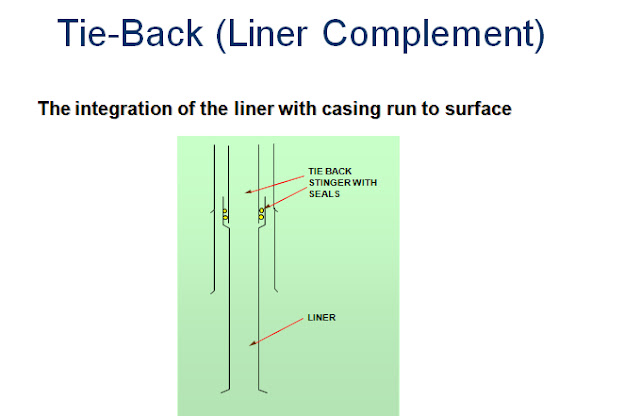

-Tie-back/liner complement:

–From top of existing liner to surface, or further up casing to cover corroded or damaged zone.

Tie-Back (Liner Complement)

Procedure for Setting Liner

-RIH with drillpipe

-At liner hanger depth, condition mud

–(Reciprocation / Rotation)

-Release slips (liner hanger)

–(Rotation - mechanical pressure - hydraulic)

-Set slips, release liner weight, check to see if running tool is free

-Pump mud - to ensure free circulation

-Cement / Displace / Bump plug / Bleed off

-Release setting tool

-POOH above TOC and circulate

–NOTE: A liner swivel can be run below the hanger to ensure that the tool can be rotated even if the liner is stuck or set.

Job Procedure Liner

-Pressure test lines.

-Pump wash/spacer.

-Pump slurry.

-Drop "Pump Down" plug (or drill pipe wiper dart).

-Displace

–To running tool

–Shear "Wiper Plug”

–Displace to Float Collar

-Bump plug/check for returns.

-Release tool.

-Pull up to T.O.C. and circulate.

Liner Overlap

-Cementing the liner “lap” is critical .

-Too much cement above the liner hanger is not recommended

-So make sure that “uncontaminated” cement is present at the liner lap - washes and spacers / WELLCLEAN II

-If not, there is communication from the annulus to the formation

Recommendations for Liner Cementing

-Ensure rheology of cement system is adequate for 100% mud removal

-Turbulent flow, if possible

-Consider 5 - 10 min. “contact time” at liner lap

-Batch mix cement

-Minimize U-tubing effect

-Rotation of liner during cementing (special bearing in tool)

-Adequate mud conditioning prior to cementing

Example Calculation - Liner

-Well Information:

–9-5/8" 47 lb/ft intermediate casing from surface to 6500 feet

–7" 29 lb/ft intermediate liner from 6200 ft to 10,500 feet

–6" open hole to TD at 14,500 feet

–Drill pipe 3-1/2" 13.30 lb/ft

–4-1/2" 16.60 lb/ft liner required from 14,400 ft to 400 ft inside 7" liner.

–Float collar 80 feet above shoe.

-Cement required to top of liner with 20% excess in open hole

*Calculate:

–Slurry Volume and Displacement

Liner Example Calculations - Results

Conclusion

-Liners have many applications

-The main feature is that normally you have small volumes of slurry and high pressures during the job.

-Liner overlap is the most critical part to cement correctly

-Even though most of the times we are not at charge of the hardware (liner hanger, cement head, etc.), we must have knowledge of what has been run in the hole, and the way it works.

-It is important to slow down the displacement to avoid excessive pressures (shear pins, end of displacement)

•Case history

•Critical water zones in a North African field required isolation with an intermediate casing

cemented in two stages. This operation increased rig time, cost and potential trouble for this

casing operation. Because the stage tool created a potential future weakness in the

intermediate casing string, the production casing had to be run to surface to cover the stage

tool and protect it from future production operations.

•The casing program was redesigned using LiteCRETE technology to replace the two-stage

intermediate casing with a single-stage casing requiring only one cement slurry. This saved

stage-tool-running time, associated rig costs and eliminated the risk associated with a stage

tool. Instead of a full production string, a production liner was then run back into the

intermediate casing, saving additional time and expense in well construction.

•LiteCRETE technology offers a well-construction solution with low permeability and low

density. Superior-quality cement columns can be pumped higher in the annulus so

multiple-stage cementing becomes unnecessary.