High Strength

Tubing Failure

Tubing Failure

Failures of high-strength tubing are normally caused by:

- Manufacturing defects

- Handling/transportation damage

- Hydrogen embrittlement

API Tubing

Connections

Connections

There are two standard API coupling tubing connections available:

The API EUE type of connection is available in 23/8”, 27/8”, 31/2” and 41/2”.

Extra Clearance

It is occasionally necessary to provide extra clearance to enable tubing

installation. To accommodate this, API couplings can be turned down (to

specified tolerances) without loss of joint strength. Special clearance collars

are usually marked with a black ring in the center of the color band indicating

steel grade. Extra-clearance, coupling-type thread forms have been developed

for non-upset tubing which have 100% joint strength.

Integral-joint premium threads provide additional clearance and are available

in a number of configurations. Some can be turned down to provide even

greater clearance. This type of joint is more expensive and is generally used in

special situations (high-pressure or gas well application).

Premium Tubing

Connections

Connections

In addition to the standard API connections, there are a wide variety of specific

joint connections available usually referred to as premium connection. Most

premium connections use a metal-to-metal seal which requires that the mating

pin and box surfaces are forced together with sufficient stress to establish a

bearing pressure greater than the differential pressure across the connection.

The bearing pressure (Pb) is defined as the pressure exerted between the metal

surfaces created by the torque used at make-up.

Premium connections are available in a wide variety of types, weights and

materials

Connection Seals

Round thread connections form several metal-to-metal seals between the tapered

portions of pin and box surfaces. The small void between the crest and root of

the mating threads must be filled with thread compound solids in order to

transmit adequate bearing pressure from one threaded surface to another.

Some connections (e.g., HYDRIL) have large smooth metal-to-metal

connections. The threads in this type of connection have a relatively large

clearance and do not act as seals. Threads like Armco Seal Lock have both a

sealing thread and a smooth metal scaling surface (Fig. 10). A Teflon ring is

used in some premium connections to provide a supplementary seal and provide

corrosion protection.

The stresses applied during make-up and subsequent service determine the

success of the connection seal. When compiling tubular make-up procedures

the minimum, optimum and maximum torque for each connection type must be

known.

Basic String Design

and Selection

and Selection

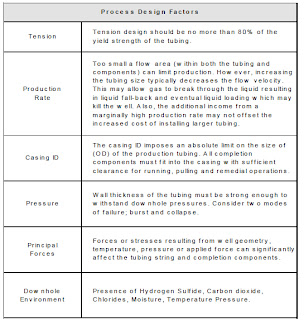

When selecting completion components, consider the factors shown below.

This of course is in addition to the basic efficiency, safety and economic

requirements of all completions.

- Facilitate installation

- Optimize production

- Simplify maintenance

- Enable stimulation or workover

- Provide for contingency

Tubular

Design Factors

Design Factors

The basic string design and selection process should take into

account the following guidelines before detailed planning is begun:

Drift Inspection

Before running in the hole, drift the tubing with an API drift mandrel to ensure

the internal clearance is within tolerance.

Handle all tubing (new, used or reconditioned) with thread protectors in place.

Do not remove the thread protectors until the tubing is ready to be stabbed.

High-strength tubing is particularly susceptible to damage caused by improper

shipping and handling practices.

Measurement

When running tubing and completion components, careful measurement of

each joint or item is essential. Each measurement is recorded in a tally book

against the joint number which should be clearly marked on each joint. The

tape used is divided into feet and decimal fractions, (e.g., the reading for 20 ft.,

6 in., would be read as 20.5 ft.).

Tubing joints (and other string components) are measured from the box end to

the beginning of the threads on the pin end (not the end). Record completion

components on a separate sheet of the tally book. The length, OD, grade and

ID are listed as appropriate for each component.

When the grade and size of pipe has been chosen, details of the following

points should be made known to field personnel:

- Handling - Tubing, especially high grade tubing (P-105, etc.)

- Torque - Too loose or too tight make-up on a joint connection

- Record (Tally) keeping - Accurate measuring and recording of

packer accidentally placed below the perforated interval is a prime

example of mis-measuring or miscounting tubing joints.

Running the

Tubing String

Tubing String

NOTE: Use PPE equipment.