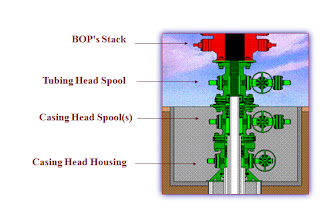

Tubinghead and X-mas tree

Tubinghead

•Surface equipment from which the tubing is

suspended

Xmas tree or valve array

•Used to control well during production

•Mounted above wellhead

•Typically sourced from same manufacturer

Primary functions of tubinghead

•Suspend tubing with hanger

•Seal between tubing and annulus

•Provide access ports to annulus

–gaslift gas

–inhibitor injection

–circulating the well

•Provide mounting for adapter flange or Xmas tree

Tubing Hanger Types

•Threaded Hanger Flange

–used in low pressure wells (e.g. Pumping wells)

•Boll Weevil Type

•Ram Type Tubing Hanger

•Boll Weevil Type

Tubing Hanger for Bowl Type Tubing Head.

Boll-Weevil type hanger and housing

Spool and Hanger

Hangers for Dual Completion

•Ram Type Tubing Hanger

–allows free tubing manipulation to latch tubing in

tension

Tubing tension hanger Cameron SRT

Tubing Hanger with Extended Neck

Hanger may have extended neck

•Projects into base of X-mas tree or adapter

flange

•Sealed flow path through wellhead

Xmas tree or adapter interface