Workovers Performed To

•Increase or restore hydrocarbon production

•Decrease water production

•Repair mechanical failures

Common Reasons for a Workover

Some of the more common reasons for a workover are:

•Repair mechanical damage

•Stimulate an existing completion

•Complete into a new reservoir

•Complete multiple reservoirs

•Reduce/eliminate water/gas production

•Reduce/eliminate water coning

•Repair faulty cement jobs

Repair Mechanical Damage

Reasons for Workover Work

Mechanical damage can take on many forms from failed tubing or downhole tools such as packers, sliding sleeves, gas lift equipment, tubing or wireline retrievable safety valves, to failed or failing wellheads. In some cases the repair can be performed without killing the well, in other cases the well has to be killed to perform the work safely.

Reservoir Simulation

Reservoir stimulation is usually accomplished by introducing a mild acid through the perfs and into an existing producing reservoir for the purpose of dissolving acid soluble solids and regaining or restoring production. This can be done by a coiled tubing unit, snubbing unit, or small tubing unit.

Completing a New

Reservoir

Completing to a new reservoir is often done when a well is drilled through multiple productive layers and the lower zone is finally depleted. The new completion might be as simple as shifting a sleeve open to allow flow, or may require that the lower zone be plugged and abandoned before the upper zone is allowed access into the wellbore.

Completing an Existing Zone

In this case the lower depleted zone is isolated with a cement plug prior to opening the sleeve adjacent to the next zone to be produced.

After the cement plug is in place and tested, the sleeve can be opened and the next zone produced

Recompleting an Existing Zone

Production tubing above the depleted zone has been cut and removed and the lower zone isolated with a cement plug. The new completion is run in the hole adjacent to the reservoir to be produced, the zone is perforated. And production begins.

Here the lower depleted zone has been isolated with a plug conveyed by either coiled tubing or wireline. After the plug has been successfully set and tested the sliding sleeve is opened allowing production from the upper zone.

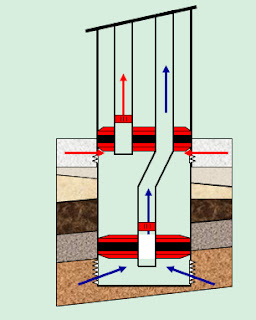

Completing Multiple Reservoirs

A dual completion, such as this one, allows for production from two zones simultaneously.

Unwanted Water Reduction

Water, the lowermost fluid in a reservoir, appears as the lighter fluids are depleted. Initial production may contain a degree of water, but the oil-to-water ratio usually decreases throughout the life of the well. Remediation for this problem can be squeezing affected perforations – but this solution is only temporary.

Water Coning

Excessive production rates can initiate water coning. Water, which may be the the drive mechanism or the lower fluid strata in the reservoir, is pulled up into the perfs. Water coning can be controlled to some extent by reducing the production rate. But, usually, the affected perforations are squeezed resulting in lower production outputs on a daily basis.

Repair Failed Cement Jobs

Evidence of a failing cement job are usually manifested as pressure appearing on the intermediate casing string and the presence of chunks of cement in the choke body. This may also be accompanied by a decrease in daily production as surface lines can become clogged with cement. Repairing this usually entails killing the well, squeezing cement into the perforations, recompleting and reperforating the well.

Unwanted Gas Production

In a gas cap driven reservoir, the gas cap expands as oil is drawn from the reservoir. Eventually the expanding gas cap can encroach on the perforations and gas production will begin. The drawbacks are: the drive mechanism is being produced and the production train may not be able to handle the gas being produced. This is temporarily remedied by squeezing the perfs. But eventually mostly gas will be produced as the producible oil is depleted.